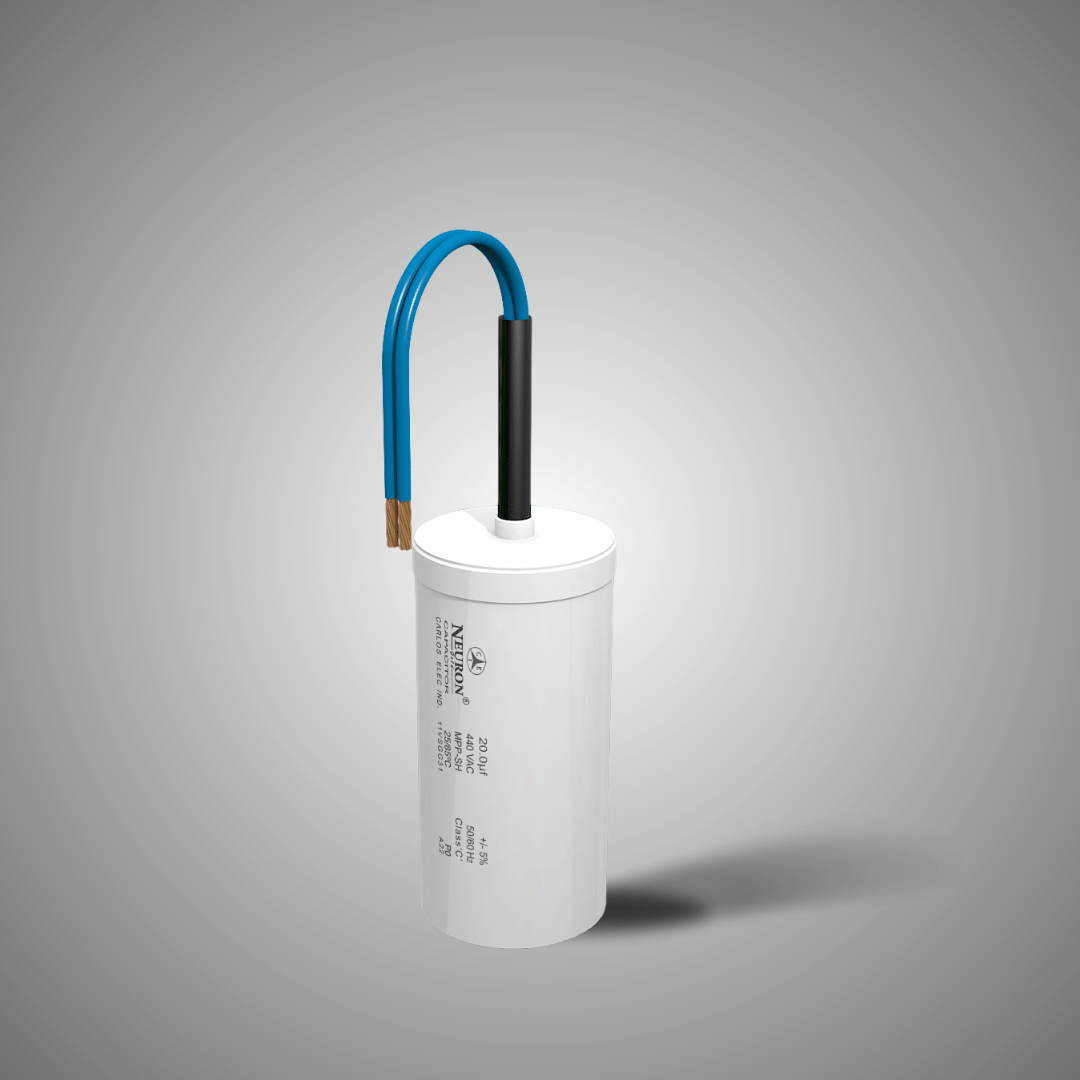

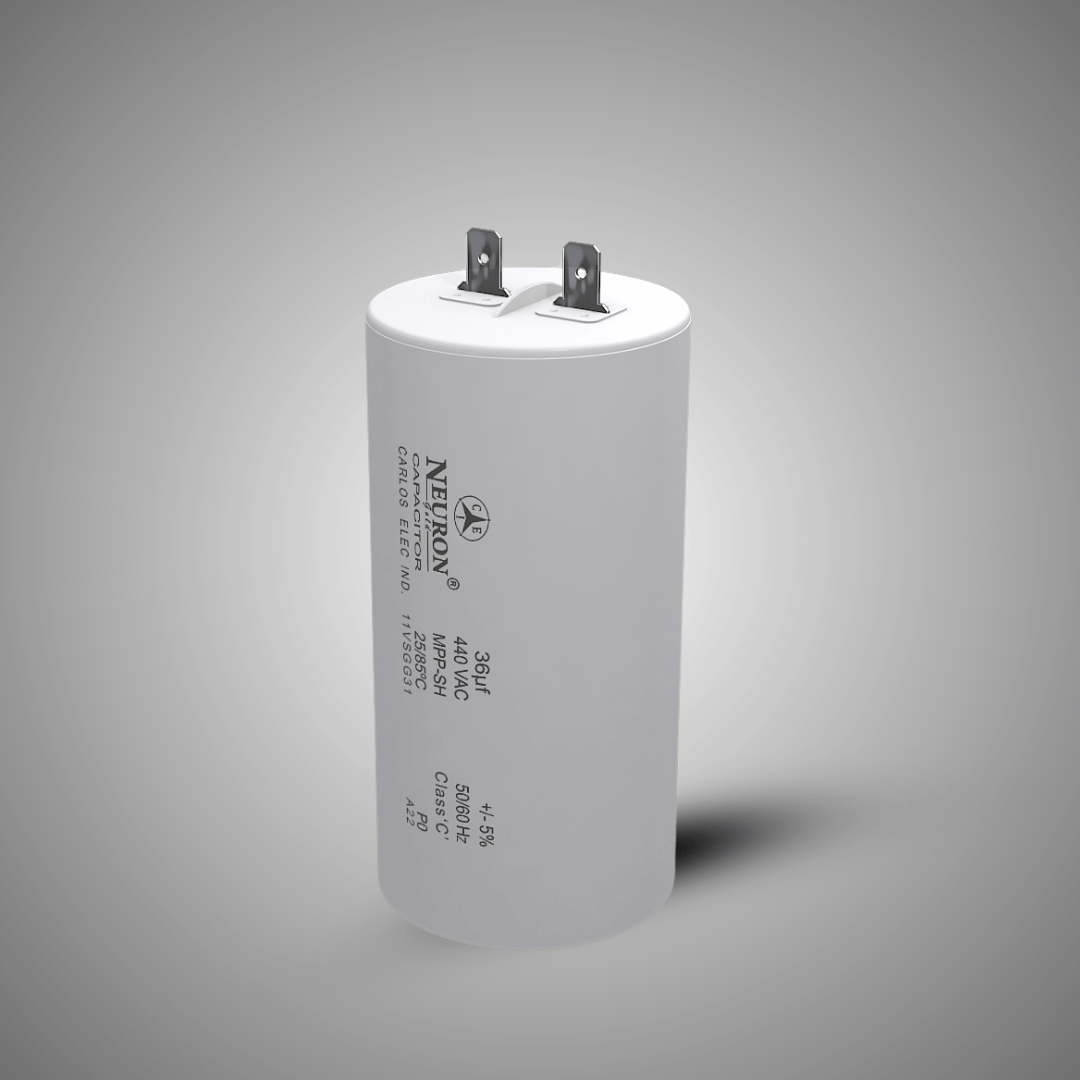

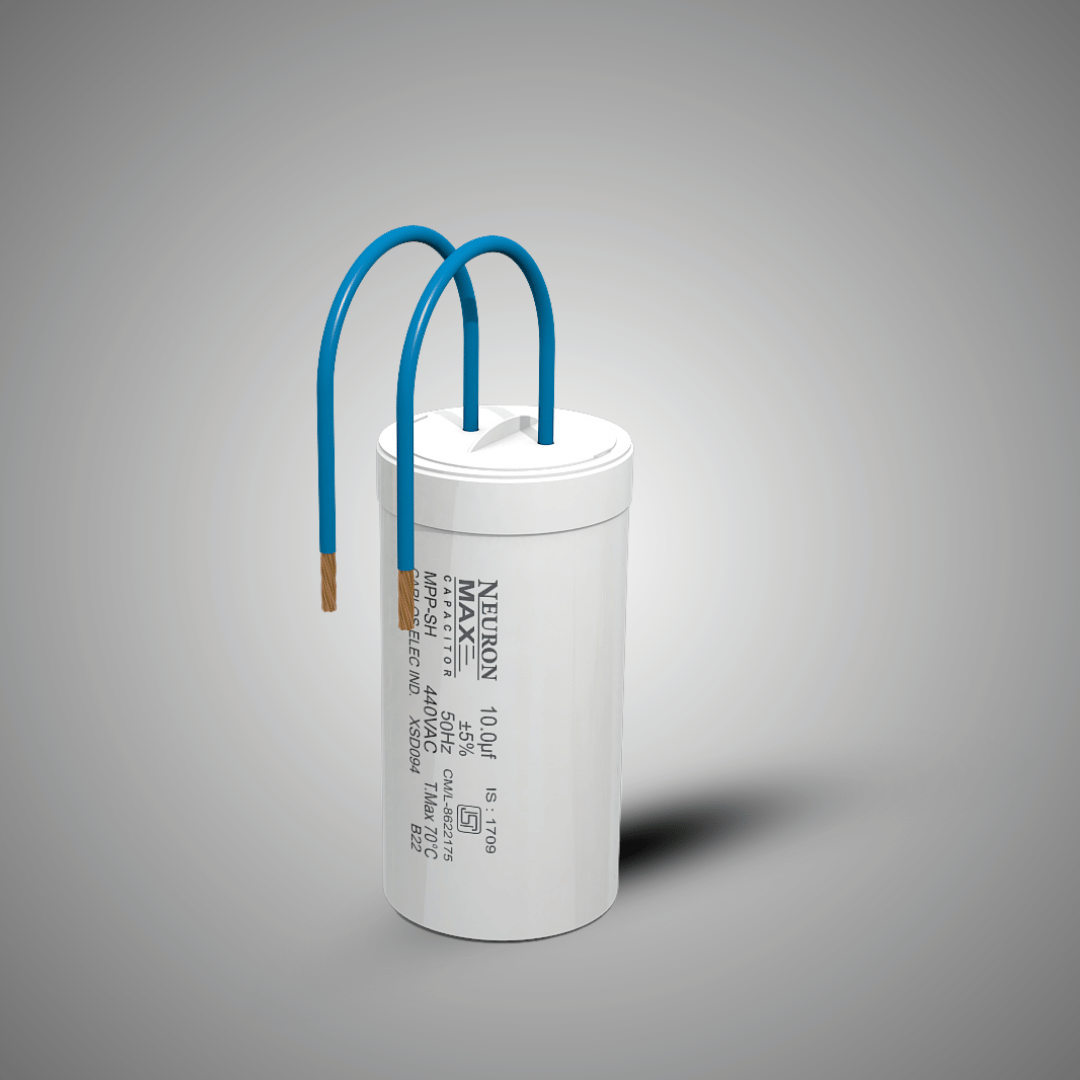

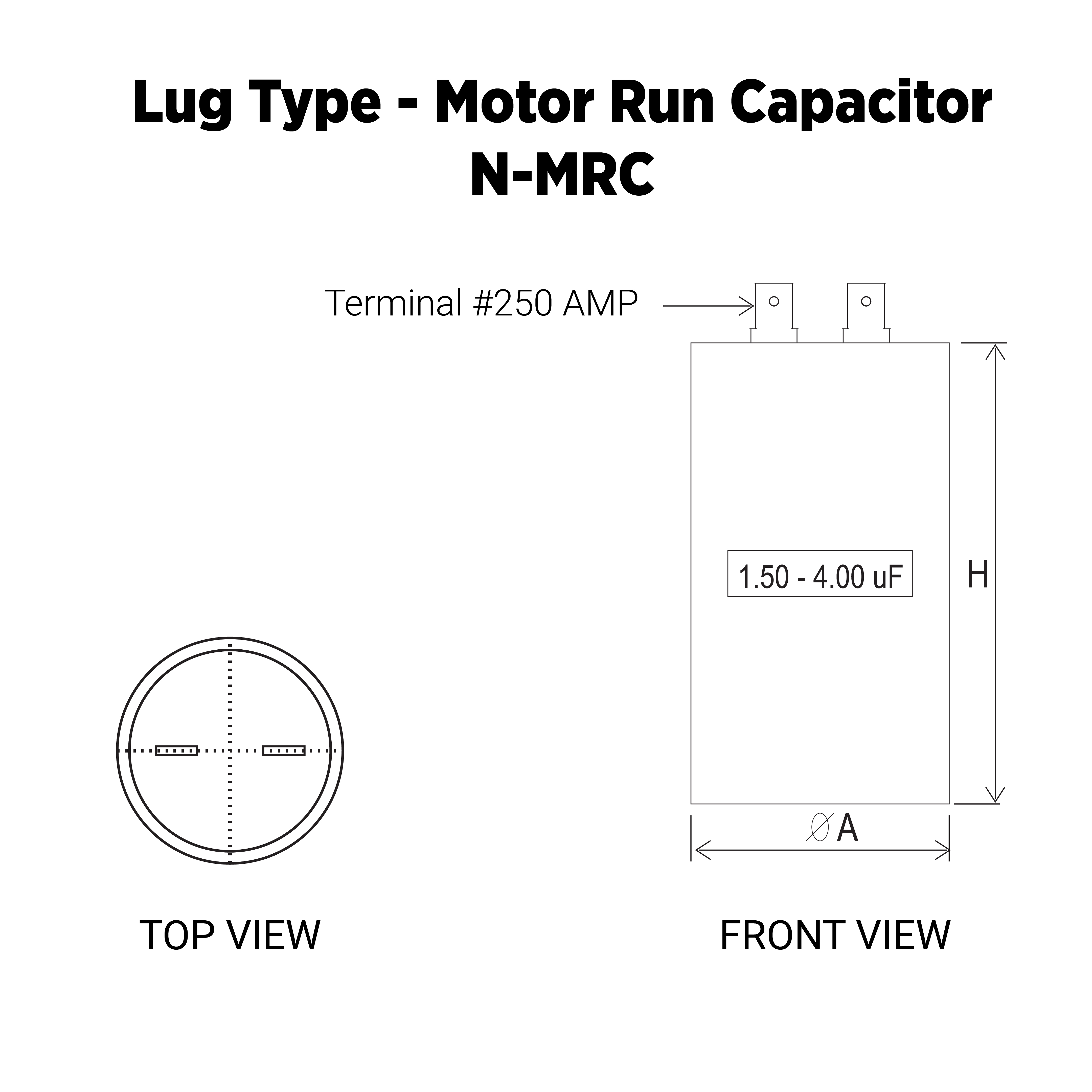

Wire / Lug Type - Motor Run Capacitor

- The capacitor is connected for the entire time the motor is in operation. The capacitance must not be too high to avoid overloading the auxiliary winding, as a result of which the starting torque is generally between 50-70% of the rated torque.

- The motor can, however, achieve performance levels equal to 90% of the rated power of a similar three-phase motor and a power factor close to 1.

- The capacitors, generally film type, chosen for this application must have a higher overload capacity, low losses, thermal stability and more silent mechanical and acoustic operation.

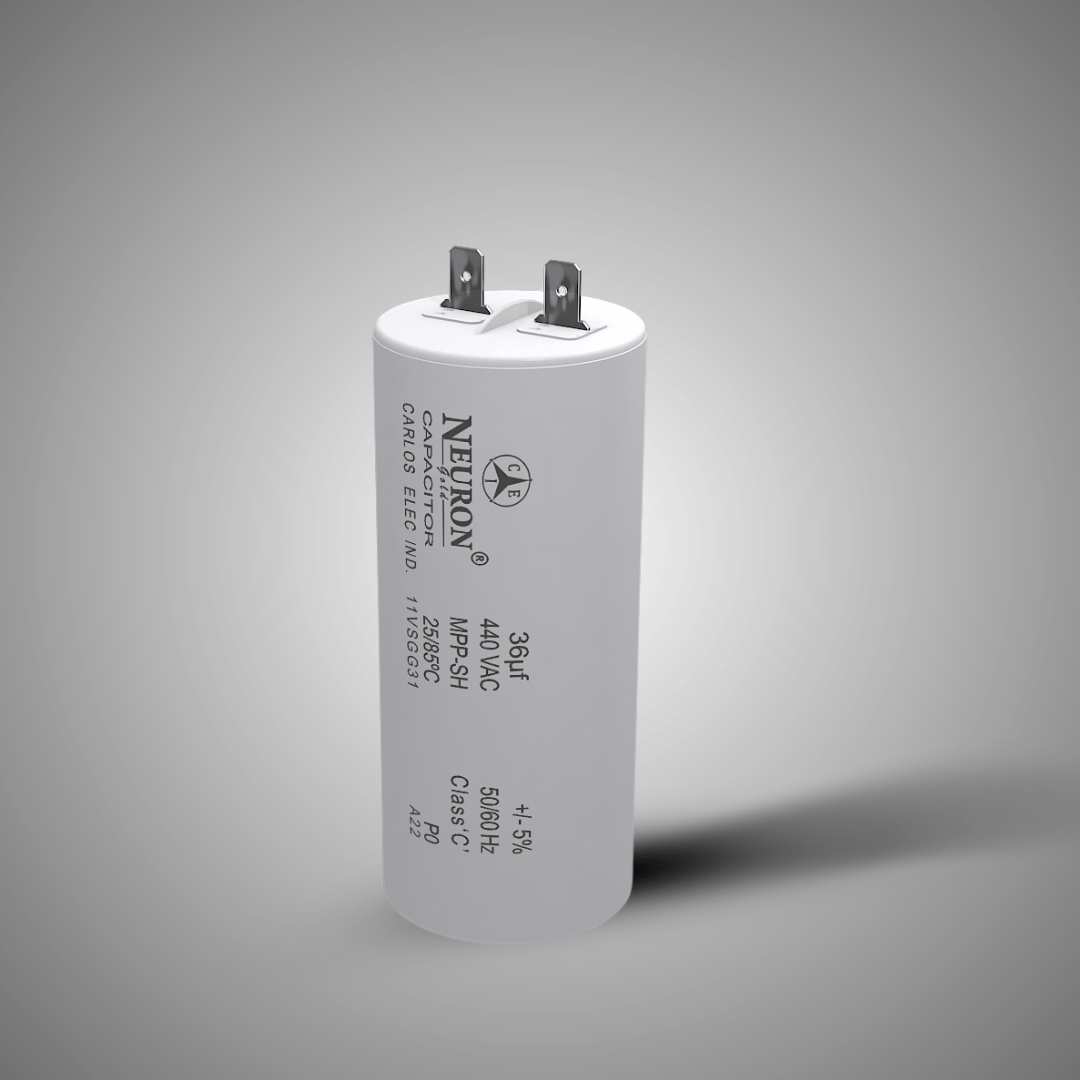

CONSTRUCTION:

- Dielectric polypropylene film with heavy edge

- Plastic / Aluminium can and top

- Filling material: PU Resin

TYPICAL APPLICATIONS:

- For general sine wave application, mainly as motor run

MOUNTING PARTS:

- Threaded stud at bottom of can (M8) as option

Mechanical and thermal properties of terminal insulator material

- Terminal insulation plastic material

- UL 94 (Ed6, 2013) compatible

- Compliance to Glow wire test as per IEC60335-1 (Ed6, 2020)

- Compatibility to RoHS Compliance to directive 2011/65/EU

FEATURES:

- Self-healing properties

- Low dissipation factor

- Available with segmented / pattern film

Design which ensures S0 - S3 safety - High insulation resistance

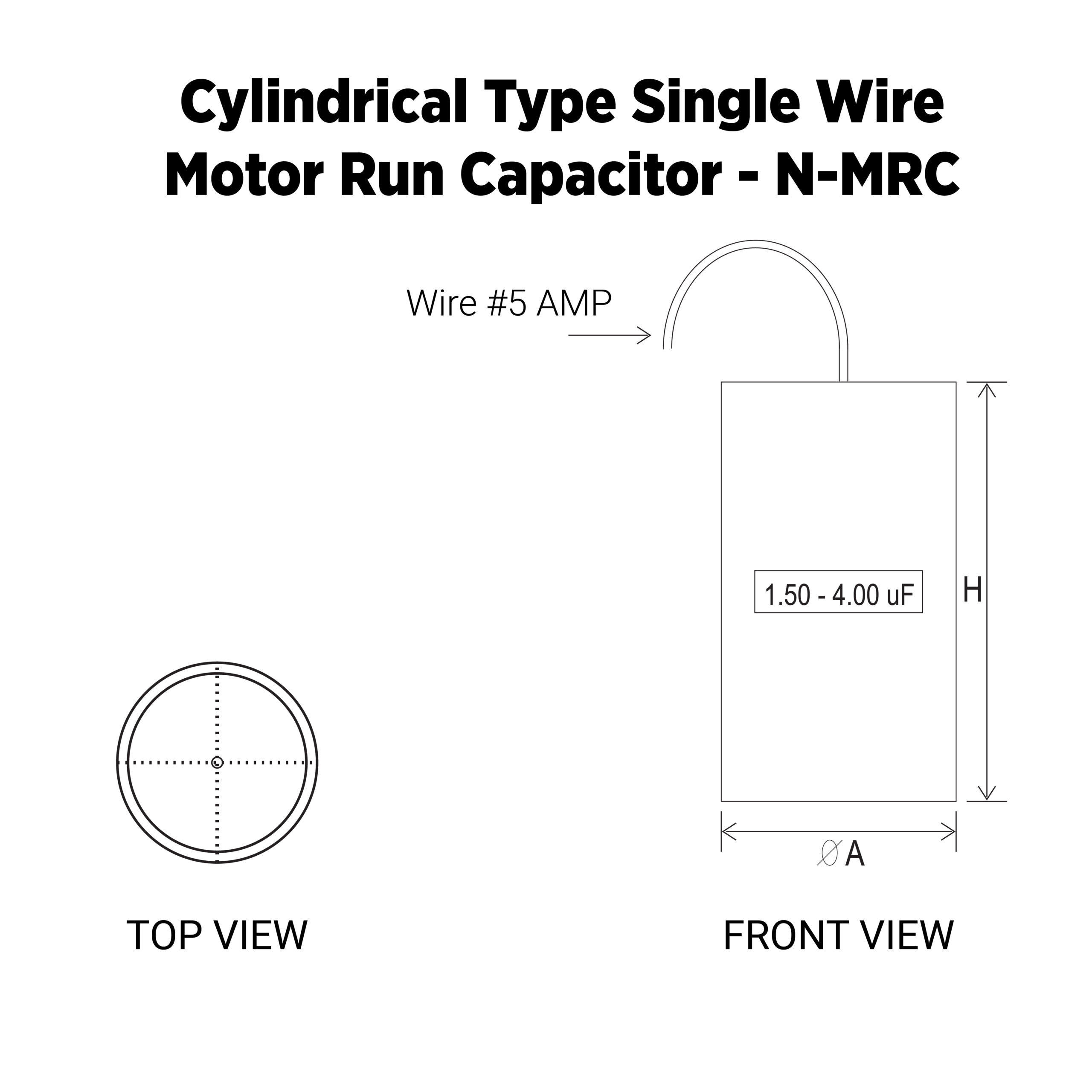

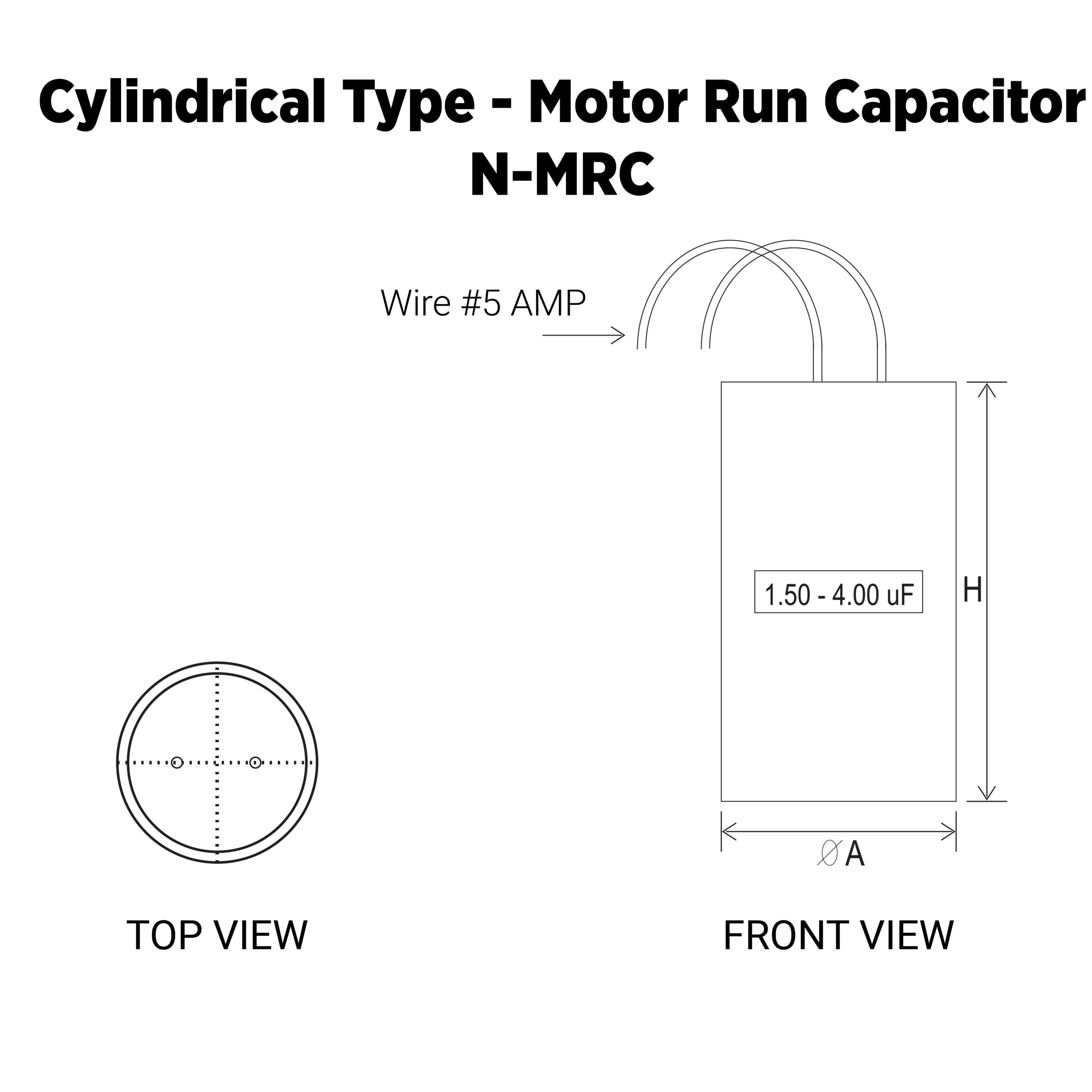

TERMINALS :

- 1+1 fast-on terminals

- 2+2 fast-on terminals

- Flexible Lead wire / Lug Type

- Insulated Cable or Lead wire with sleeve

APPROVALS:

-

TECHNICAL SPECIFICATIONS

Reference Standard

IEC 60252 ; IS 2993 ; UL 810Safety class to IEC 60252-1:2010

S0 – S3Life expectancy to IEC 60252-1:2010/AMD1:2013

450 V : 10000 h (Class B/Class B)UL 810

Approved componentRated capacitance CR

0.5 uF to 100 uF ;Tolerance Tx

± 5%,Rated voltage Vrms

440/500/600 V AC, others on requestRated frequency fR

50/60 HzElectrical Test

AC test voltage terminal to terminal VTT, rel.

2.0 X VR, 2 s (routine test)AC test voltage terminal to can VTC

2000 V AC, 2 s (routine test)Insulation resistance Rins or time constant at 20 °C Humidity ≤ 65% (minimum as-delivered

values)

10000 OhmsDissipation factor tan δ at 20 °C

≤ 2 x 10-3 (1 kHz)Maximum rate of voltage rise dV/dt

max 10 V/ µsClimatic Data

Climatic category

40/85/21Lower category Tmin

–40° CUpper category Tmax

+70/85° CDamp heat test ttest

21 days